Peyton Beals

The first Ph.D. degree that Dr. Robert Duncan Enzmann earned was in geology. As I also possess a degree in geology, I understand the allure of fascinating rock samples and beautiful mineral specimens. Sometimes these items are of academic or economic interest. Other times they are simply appealing and aesthetic. The Enzmann Archives include a large assortment of geologically related materials that probably fall into both categories. During my initial inventory of the collection, I encountered a container of brightly colored, highly lustrous, material that defied immediate identification.

One possible origin was so-called slag glass. Slag glass is a byproduct of metal smelting and extraction. As metal ore is smelted (heated and melted), lighter materials in the host rock liquify and congeal. These components will ‘float’ above the molten metal and will cool once they are either taken off the top or the molten metal is drawn from the bottom of the crucible. If this cooling is rapid enough, the process of vitrification (glass formation) takes place and slag glass can be created. The resulting material is primarily silicon dioxide but can contain multiple and numerous impurities that account for a broad range of colors and properties. Historically, this material was discarded onto the ‘slag heap’. Recently, it has found purpose as an ingredient in concrete or in landscaping as filler for pathways and plantings. Dr. Enzmann was involved with mining operations and metal production (especially copper and beryllium). So, it is not unreasonable that he might have acquired some examples of slag glass during his geologic career.

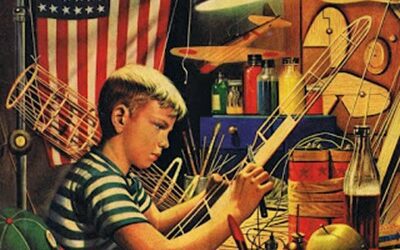

Upon closer examination, I became increasingly convinced that the material was synthetic and manmade, but there were still attributes that argued for a natural origin. Most of the material was glass-like in appearance. It was almost perfectly transparent in a wide range of hues from crystal clear to almost black (please see Figure 1).

Figure 1

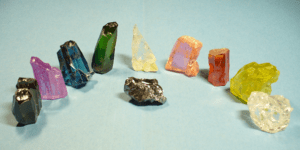

A majority of pieces exhibited a highly lustrous and adamantine (gem-like) finish. Under magnification, there did not appear to be any inclusions or flaws that are prevalent in naturally occurring minerals. It broke into conchoidal shards much as glass should. However, it was quite heavy and seemed to possess a higher specific gravity than common glass. It was also very hard and tested, on the Mohs scale of hardness, above what would be, typically, expected for glass. Further, there was evidence of crystalline or, at least, pseudo-crystalline structure (please see Figure 2).

Since glass is an amorphous solid (or an extremely viscous liquid), no crystal faces or cleavage should be observed without secondary processing such as cutting or molding.

Figure 2

Photo – FREA

Further investigation yielded more unusual characteristics. Some pieces were covered with what, ostensibly, appeared to be a white powder, but were actually a rather robust glass-like “froth” or frosting (please see Figure 3). This frosting seemed to have formed as a crust over the more transparent and ‘crystalline’ material.

Figure 3

Photo – FREA

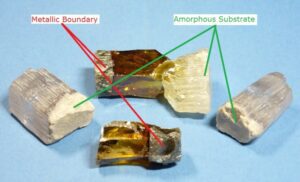

A few of the specimens included, or were attached to, a very distinct boundary or interface that gave the impression of having metallic properties. The incidence of ‘crystal’ structures was more pronounced at this interface with some of the crystal-like structures appearing to emanate from the boundary (please see Figure 4). This type of crystal formation, from a substrate, is common in nature. Hydrothermal percolation through rocks containing voids can often deposit carpets of large crystals that grow outward from the interior surfaces of the cavities. This creates a crystalline sheet known as druse that is attached to a less crystalline, amorphous, substrate (often chalcedony). It was possible that the bright and shiny things were formed in a similar process.

Figure 4

Photo – FREA

Finally, there was evidence that lapidary work had been performed on some of the pieces. It was obvious that several of the pieces had been cut with a saw as the surface was unnaturally flat and, circular, tool marks could be observed. This added intrigue since such effort is usually reserved for rocks and minerals that possess some intrinsic value either academic or monetary.

After the better part of a day, I was still perplexed as to the true nature of the bright and shiny things. Without access to a more comprehensive chemical laboratory or the aid of advanced equipment such as a polarizing microscope or X-ray crystallography, it was difficult to take the examination much further. I finally surrendered and resigned myself to temporary defeat. In lieu of a better idea, I sorted the material by color and returned it to the original container. I attached a label with some noncommittal comments as to the identity of the contents and promised myself to pursue the problem again “some other day”.

Some other day came much sooner than I expected. Less than two weeks later, another container of bright and shiny material was delivered from Dr. Enzmann’s estate, in Maine. The appearance of the material was virtually identical to what I had already inspected: a similar color spectrum, the same luster, the same weight, and hardness. However, there was one momentous difference in this container. Dr. Enzmann (or someone) had left a clue. Clearly written on one of the plastic bags were the words, “H-F washed” and “ZrO2”.

I took “H-F washed” to mean that the specimens had been washed with hydrofluoric acid and ZrO2 is the chemical formula for the naturally occurring mineral baddeleyte (zirconium dioxide). Baddeleyte can also be synthesized in the form of a white powder, zirconia, which is utilized in ceramics and dental appliances (implants). However, if zirconia is blended with 10% yttrium oxide (Y2O3) and fused at a very high temperature (above 3,000 °C), the diamond substitute, cubic zirconia (cz), is created. The bright and shiny things are, most likely, thousands of carats of cubic zirconia!

The synthesis of cubic zirconia was perfected in the Soviet Union in the early 1970s. A process known as the Skull Crucible Method was developed and refined. In brief, the method involves blending the zirconia, yttrium oxide, and some metal chips in a thin crucible of cubic zirconia. Trace impurities such as copper, chromium or cobalt are also added to imbue color. The crucible is then placed in, external, liquid cooling coils while being, internally, heated through high-energy radio frequencies (RF). The metal chips rapidly heat due to the RF (much like a microwave oven) and melt the zirconia and yttrium powder. Crystallization is initiated once the melt is complete and cooling begins.

A variation of this approach has been employed in the United States in which the powder is placed in an iridium crucible and heated with electrical coils rather than high-energy RF (please see Figure 6).

Figure 5

By Larry P Kelley at English Wikipedia – Own work, Public Domain

It is probable that the material in the Enzmann Archives was created in this fashion and that its origin is from the Shelby Gem Factory in Shelby, Michigan. Figure 7 is a photographic comparison between the Enzmann Archives material (left) and the cubic zirconia that was once produced at the Shelby Gem Factory (right). The similarities are compelling.

Figure 6

Photo – FREA

Figure 7

By Larry P Kelley – Self-photographed, Public Domain

Why this material is in the Enzmann Archives remains a mystery. I now know the “what” and perhaps the “where”, but not the “who, when, or why”. The Enzmann geologic documents contain reports on the Synthetic Pegmatite Project. Pegmatites are igneous rock intrusions that often develop large mineral crystals of varied chemistries. I had thought that this material, now known to be cubic zirconium, might be related to those studies on synthetic pegmatites, but a more thorough reading of those reports suggests that this is probably not the case. It may be that Dr. Enzmann was curious about the cubic zirconia process and went to observe, or advise, and returned with some souvenirs. I will continue to be vigilant for more documents that could tie this material to one of Dr. Enzmann’s endeavors.

While the rough cubic zirconia is certainly beautiful, it is not particularly valuable. Literally, tens of millions of carats of cubic zirconia are now produced in Russia, India, and China on an annual basis. Large pre-cut gems, in every imaginable color, are available for less than $50 in lots of 100 stones or more. However, should the kind reader of this modest article care to make a (tax-deductible) donation to FREA, a selection of brilliant baubles, direct from the Enzmann Archives, would be gladly sent to demonstrate our appreciation.

If things of the mysterious fascinate you, pick up a copy of The Capital Line – a most astonishing discovery that has never been seen in recent historical records on planet Earth. Yet it is there for the seeing for those who know how! Click here to get your digital copy for only $2.97!!